Frequently Asked Questions

Find the answers to all your questions regarding our technology and our products. In case you still have unanswered questions, do not hesitate to contact us.

- Focal Molography is a nanotechnology-based bioanalytical method that combines surface chemistry, molecular self-assembly and state-of-the-art lithography technology. Central to it is s biological surface structure termed mologram, which is part of our patented sensor chip. Bound biomolecules on the mologram function as “detectives” that recognize the target analyte in the sample through molecular recognition and selective binding and thereby changing a light signal.

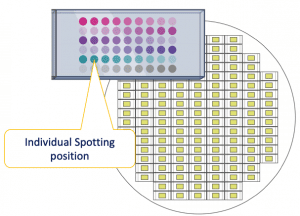

- Yes, each mologram can be read independently because it has its own focus point. As long as the binder is specific to one target there is no crosstalk to other targets.

- Yes, multiplexing is achieved via existing spotting solutions with commercially available solutions. With our pre-functionalized kits from our web shop, you can either place a joint project and we will produce your fitting turnkey chip for you or you can make conjugates yourself and put them on the chip with single injection.

- The amount of optical material in such a hologram required to unambiguously detect a change in diffracted intensity is less than 10 fg. 50 SAv with 4 fg / mologram.

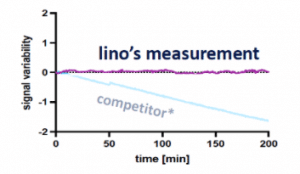

- Due to our intrinsic self-referencing principle of the mologram the sensor does not need temperature stabilization to achieve a stable signal.

- Due to the unique quadratic dependency of the signal-to-noise we can achieve high sensitivity with minimal optical straylight optimization.

- Due to the physical principle we achieve the same signal resolution by measuring our light signal with a 10% accuracy compared to a required accuracy of 0,01% in angle for SPR.

- Due to the sensor materials, we are already compatible to existing integrated photonic solutions on the market.

In classical electronic microfabrication small defects can easily result in a total loss of the product. The fabrication of molograms in comparison is much more robust since small defects can influence the result but don´t lead to a total product failure.